|

||

|

|

History Previously known as the Particle Physics Silicon Laboratory it was created to play an important role in assembly work for detector components for Particle Physics experiments such as the ATLAS detector for the LHC This is not an extensive list at the moment and will be expanded as we search our project archives. Take a tour of our past achievements and the equipment that did it.

Clean room pictures from 1998. The Particle Physics Silicon Laboratory was opened in 1998 with funding by PPARC. It's main purpose was to assemble parts for the SemiConductor Tracker inner barrel for the LHC ATLAS detector. Included in the pictures is Ian McGill (Who was the original wire bonder operator, up until around 2001) with Tony Carter (One of the SemiConductor Tracker project leaders) on the right. Ian is sitting in front of the Delvotec 6319 which played a major role in the project, this machine was bought secondhand for about £60,000. This clean room was class 100,000 (Which required only overshoes to be worn) and was based in the Poynting Physics basement. The facility has since moved to Physics West. One of the features of this clean room was a very large and extremely heavy tooling plate table that was ideal as a precision work surface.

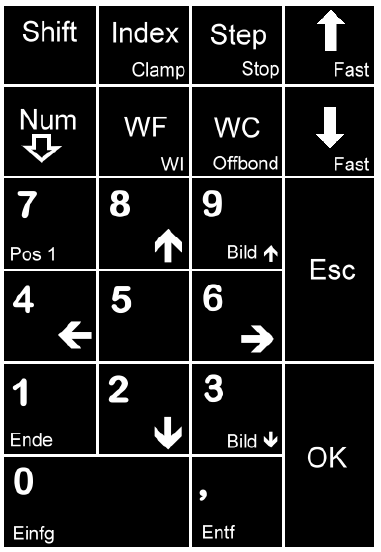

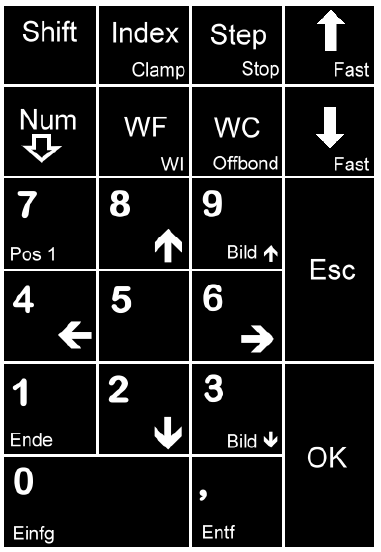

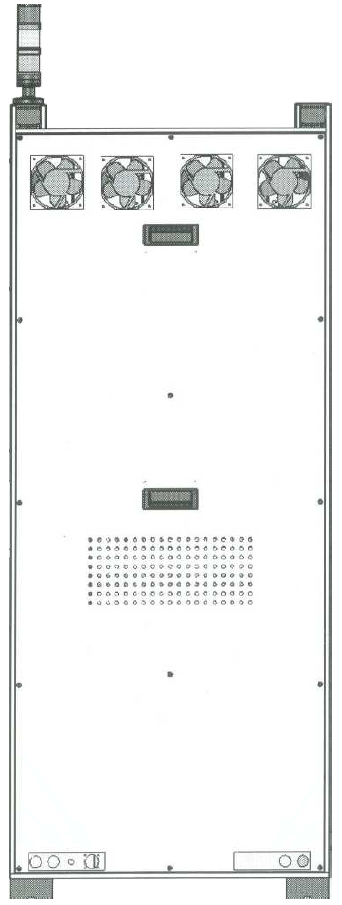

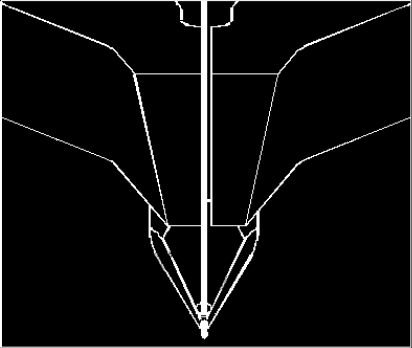

F and K Delvotec 6319. This machine played an important role for the Particle Physics Silicon Laboratory in the LHC ATLAS Semiconductor tracker project. It's purpose was to wire bond the ATLAS ABC readout ASICs that has been glued onto the Hybrids. This machine was designed in 1993 by F and K Delvotec who are based in Austria. Actual date of manufacture is unknown but it would have been around the mid 90s. It features the patented Bond Process Control system which enables it to control the bond foot deformation and compensate automatically for most quality control issues. Towards the end of it's working life the Pattern Recognition system permanently failed, however the machine could still function without it, manual alignment could be used instead and this kept it going for a few years more. It is currently located in another clean room on the campus. It featured an early Cognex Pattern Recognition system for automatic location of the wire bonding pads, this enabled it to run in fully automatic mode.

ATLAS Semiconductor Tracker Hybrids. Our part of the ATLAS project was to work in co-operation with RAL, Cambridge and QM London to produce a total of 709 detector modules which was mounted on the ATLAS Semiconductor Tracker inner barrel detector. Other information about the ATLAS SCT project can be found on the CERN ATLAS SCT webpage page. Some interesting statistics for the project done at Birmingham:

These Hyrbids are now currently buried deep within the ATLAS Detector and are part of the apparatus used to detect and collect collision events on the project.

Dage BT22 pull tester. This pull tester was bought second hand in around 1998 and even then it was a vintage machine. Markings inside the machine suggest that it was designed and possibly built in the early 80s. When the Dage 4000 was first installed in the clean room an engineer from Dage was present to help with the setting up, he was extremely impressed to see a BT22 still in perfect running condition. It is currently in storage and it may even may be used again one day. Despite it's age it has perfomed extremely well, it has been carefully maintained and still works to this present day. Pull test results are printed out on rolls of thermal paper (Which is not very clean room friendly!) this is the same kind of paper that is used in cash tills. |

|

|

|